SERIES 400

MODULAR TEST SYSTEMS

Our innovative and multifunctional Series 400 excels with customized testing solutions based on a modular kit of proven and tested standard components. Your advantage: You receive your individually configured test system under the conditions and with the reliability of a standard solution that precisely meets your requirements.

SERIES 400 – DEVELOPED FOR THE DEMANDS OF OUR CUSTOMERS

With numerous combinations of different test types, you will find your individual and reliable testing solution in Series 400. Series 400 impresses with its adaptability, as it can be flexibly and universally integrated into various environments. Moreover, it stands out with its intuitive usability and high system availability.

100 MODULAR VARIANTS – CUSTOMIZED TO YOUR TESTING REQUIREMENTS

RELAY MATRIX - FOR THE MULTIPLICATION OF TEST POINTS

AUTOMATIC FUNCTION TEST ADAPTERS (DUMMIES) FOR REGULAR VERIFICATION

CONTACTING THE TEST OBJECT - STANDARDIZED OR INDIVIDUAL SOLUTIONS

COMBINABLE WITH ADDITIONAL ETL SERIES COMPONENTS (TEST BENCHES, TESTING FIXTURES, TEST SCALES)

OPTIMAL INTEGRATION INTO HIGHER-LEVEL SYSTEMS INCLUDING RESULT TRANSFER

DIVERSE INTEGRATION POSSIBILITIES IN AUTOMATED PRODUCTION SYSTEMS

SERIES 400 – LEADING IN SAFETY AND INNOVATION.

With Series 400, we guarantee worry-free electrical safety inspections according to common VDE standards and EN standards, where measurement accuracy and the reproducibility of the measurement take precedence – even with high production quantities!

ATS400 – THE COMBINATION TESTER THAT ADAPTS TO YOUR REQUIREMENTS

The combination tester ATS400 is the centerpiece of the 400 series family of devices. This universal testing device contains high-precision measuring technology and various control components. Thanks to its modular design, the safety tester combines a variety of test types, optimally and flexibly adapted to any testing task, in a single compact and portable device. Additionally, we always provide the suitable operating variant and the corresponding control concept – regardless of your testing requirements and for any application.

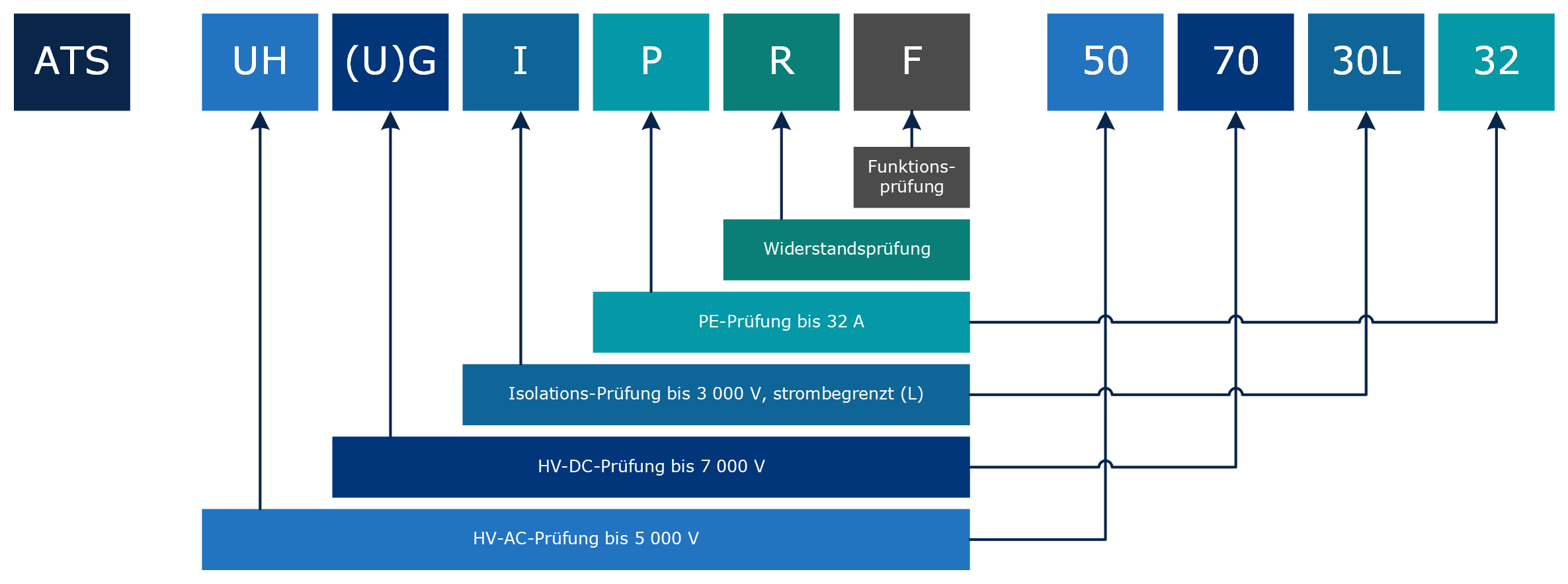

SERIES 400 – THE NOMENCLATURE.

The straightforward nomenclature of our devices directly reveals which testing modules are installed in each variant. We have illustrated this for you with our ATS-UHGIPRF507030L32:

HYBRID RELAY MATRIX – EASY EXPANSION OF TEST POINTS

The ATM400 effortlessly multiplies the measurement outputs to the desired number of test points, and it can be expanded as needed. With the automated test sequence, you can check all measurement points according to a predefined test plan. The ATM400 is suitable for all types of tests with high voltages and currents, available as a single-pole or two-pole variant for four-wire measurement technology and contact monitoring.

NORMATIVE FUNCTIONAL CHECK – ERROR SIMULATION WITH THE TEST DUMMY FROM ETL

For your process safety: With our test dummy (or also measurement master), you can demonstrate that your test unit functions flawlessly. This dummy is cyclically introduced manually or automatically into your testing process to test the testing devices or testing system according to VDE specifications. The dummy replaces the actual test object and intentionally simulates a good and faulty case. This tests whether the testing facility recognizes the error simulation.

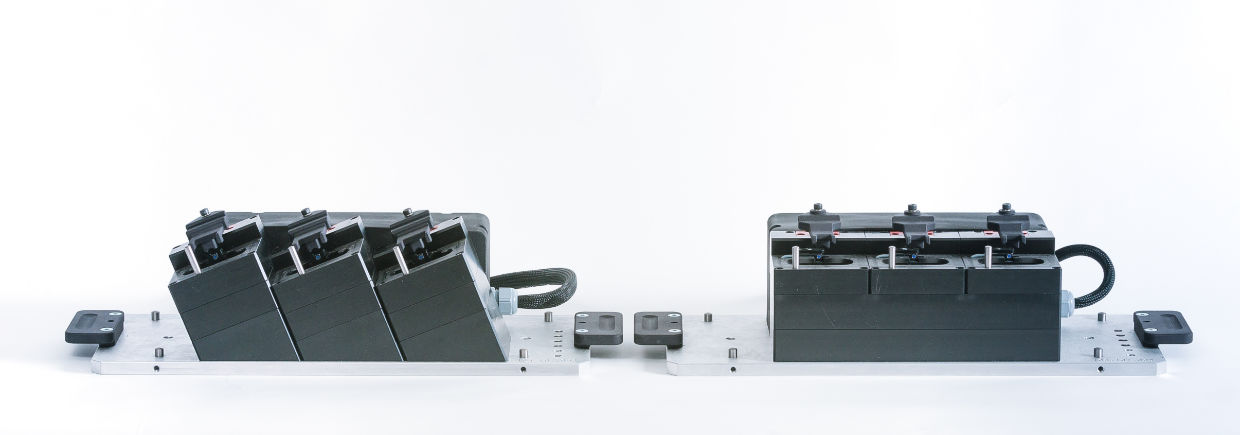

TEST ADAPTERS – ELECTRICAL CONTACTING OF YOUR TEST OBJECT

The electrical contacting is the connection between one of our test devices and your test object or specimen. This contacting is also referred to as a “test adapter.” At ETL, you can obtain both high-voltage compliant standard contactings and custom-made customer-specific test adapters (special construction). Many options are available, such as contacting via standard sockets, test clamps, Kelvin clamps, bushing plugs, contact pins, ball baths, test forms, or custom connectors according to your preferences.

Fully electronic testing system

Exact test voltages and currents for a reproducible and wear-free test. All test parameters are constantly regulated and, due to full electronic generation, are independent of any mains voltage fluctuations.

Safety circuit with two force-guided safety relays (TÜV certified)

The safety technology is implemented as required by EN 50191. There are 9 different wiring options available to test in compliance with standards using test pistols, test cages, two-hand operation, or within a transfer line.

Menu-driven test sequences: Manual or fully automatic

The user can choose between individual testing of the available test modules or testing with a predefined, freely configurable test plan. Tests via a test plan run reproducibly in production and support testing personnel with clear status and error messages.

Automation of test tasks via internal relay matrix

The test object only needs to be plugged or contacted once. The switching between different test tasks is automated and realized through an internal relay matrix.

Operator instructions and digital photos

Various instructions and digital photos can be displayed before and during the test or in case of an error, guiding the operator optimally through the testing process.

Start automatic

The start signal is triggered by pressing the test pistols (Patent). The voltage is only switched on when both test probes are securely in contact with the test object. This protects the test object from voltage peaks and ensures the required test time (functionality depends on the chosen test types).

Monitoring of test lines for conductor breakage and monitoring of contact with the test object

The high-voltage lines are implemented in 4-wire technology (Patent) to achieve maximum process reliability (functionality depends on the built-in test modules).

Shutdown via Limit Detection, Arc Detection, and Peak Detection

Multiple criteria are available to reliably detect insulation faults. In addition to exceeding the current limit, triggering a specific overcurrent detection also leads to an error. This allows even low-energy breakdowns to be reliably detected.

Ramp function and detection of breakdown voltage in high-voltage tests

The voltage ramp is switchable, and parameters (such as rise and fall time) are freely selectable. The ramp function ensures a particularly gentle test and is mandatory when a product standard prescribes a specific voltage profile. Additionally, the voltage value at which an error was detected is recorded.

All test tasks are individually parameterizable

All parameters such as test voltages, test currents, limits, test times, start options, operator instructions, matrix settings, sequence options, and test order are freely configurable.

Individual settings for

Language settings, user management, memory options, behavior of digital inputs and outputs, acoustic signaling of status and error states, options for contact and cable break monitoring, file manager for test plans and result files, and more.

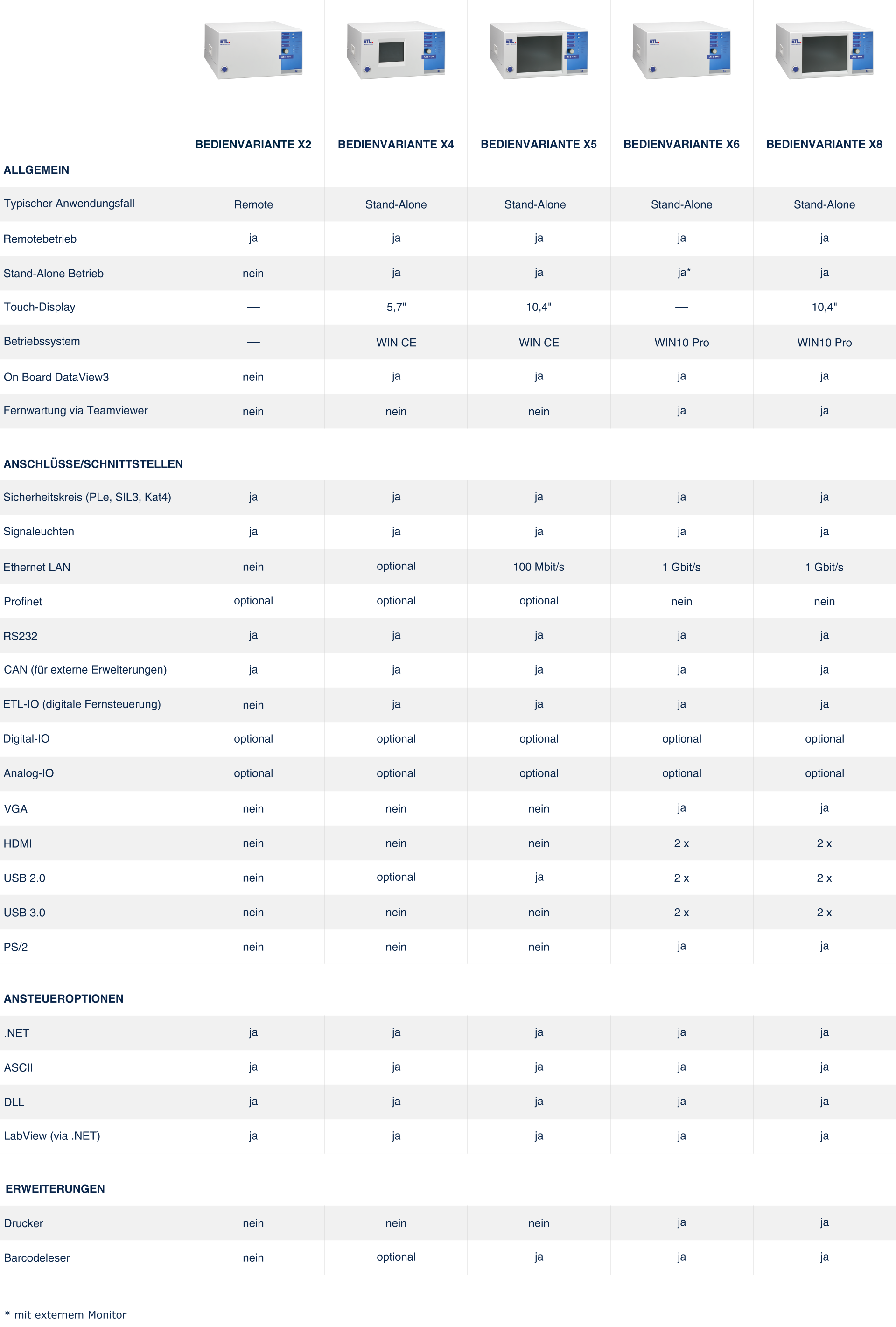

Testing device for “stand-alone operation” or for remote control via interfaces

The testing device can be remotely controlled via PC software (ETL DataView interface), customer-specific applications (DLL, .NET), simple command parameters (ASCII), or digitally from an PLC (Digital-IO).

CAN interface for connecting external expansion modules

The testing system offers the possibility to connect external modules and measurement tasks via an ETL CAN interface. This allows the system to be expanded with a matrix for multiplying test points, 1- and 3-phase power sources for functional testing, or even a hot HV test under mains voltage conditions.

Error notification: Acoustic, visual, and via interface

Faulty test objects can be reliably detected. Additionally, the type of error is displayed and documented in the result file.

Upgradeable via interface and remote maintenance

Customer-specific changes and updates can be implemented via the interface, and for PC-based systems (X6 or X8), remote maintenance is possible using TeamViewer.

OUR SALES TEAM IS READY FOR YOU!

Our contact options:

Email: info@etl-technologies.ch

Phone: +41 56 485 89 89

REQUEST NOW!

Click here to get to the testing device in two minutes – fast, easy, and without obligation.

Answer questions, provide contact details, and you’re done!

We will definitely get in touch with you.